Cylinder Block Resleeving

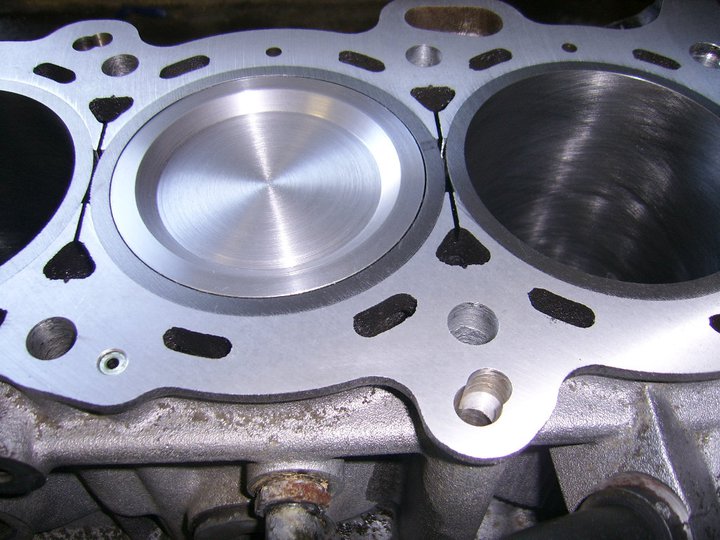

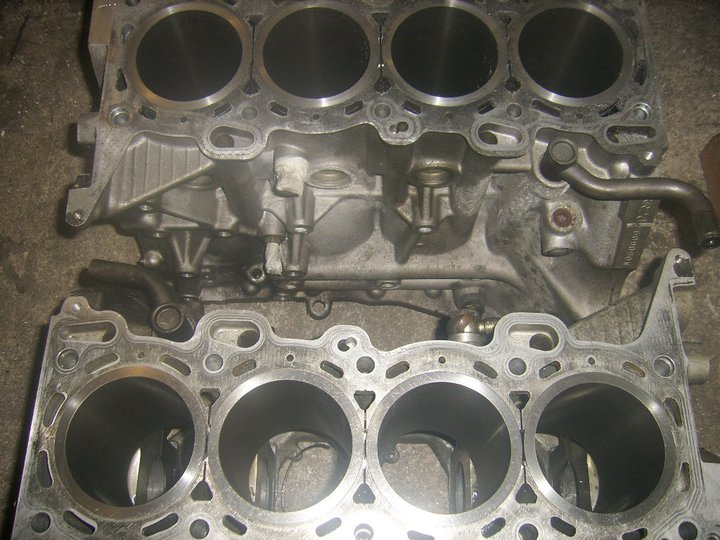

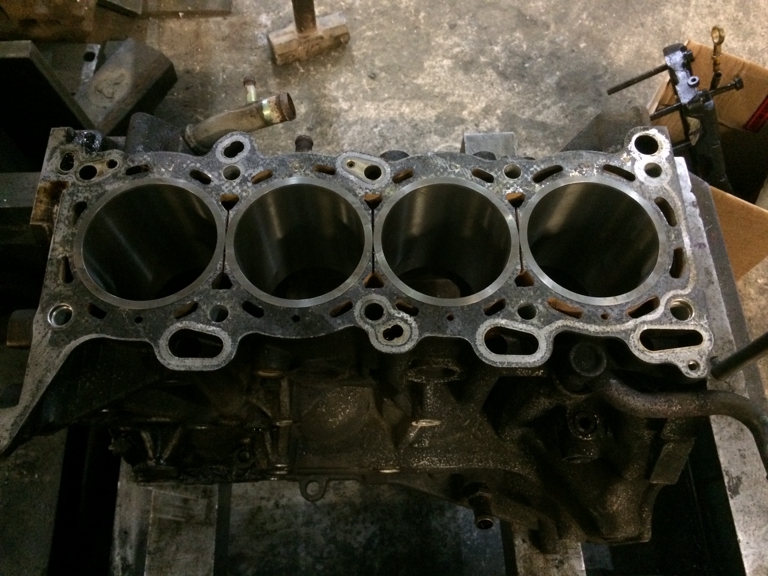

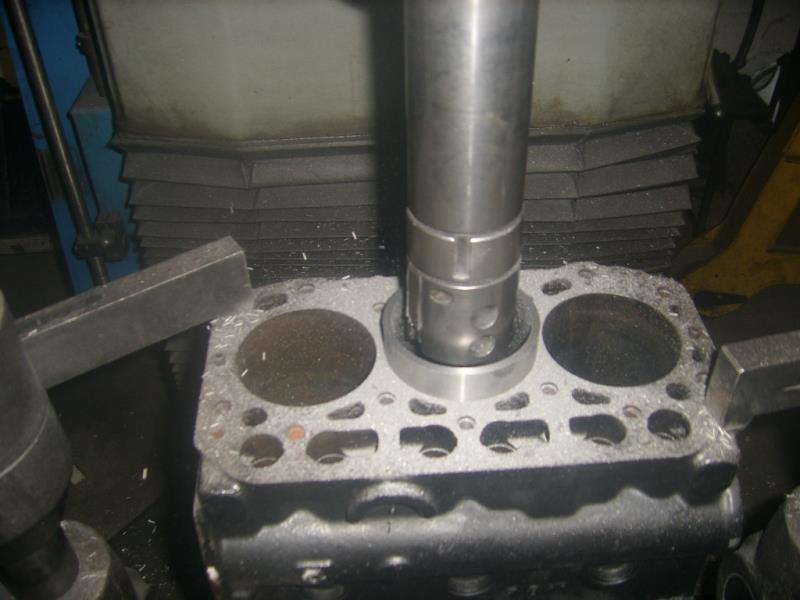

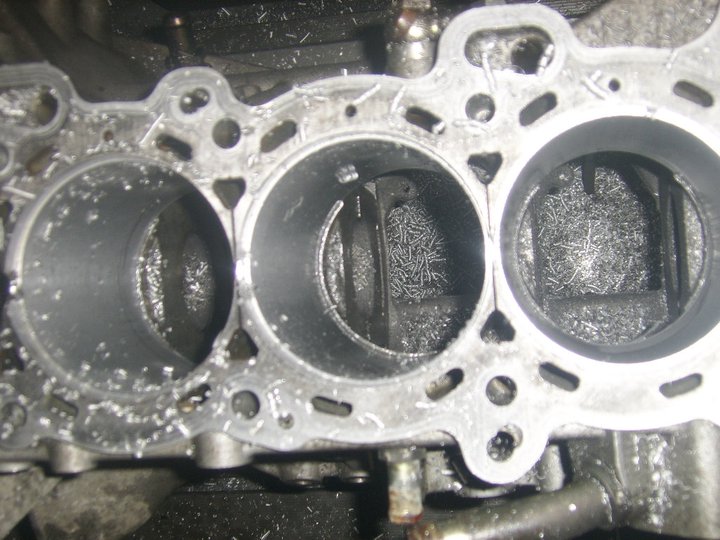

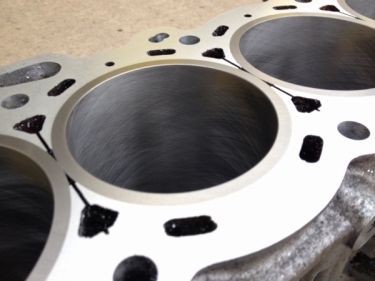

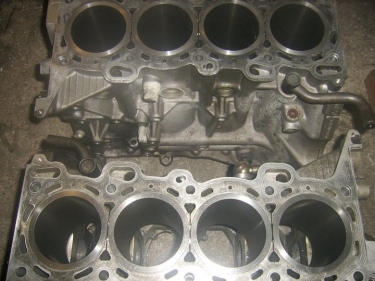

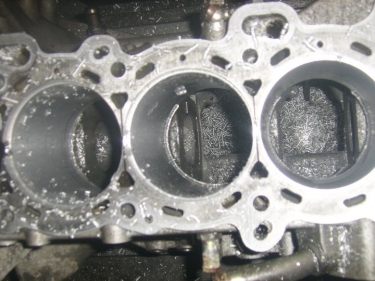

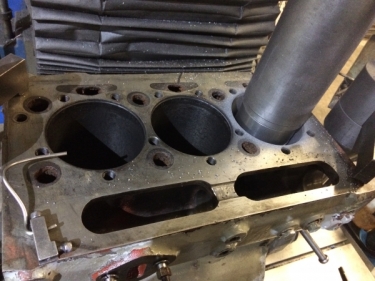

Damaged and worn cast iron and aluminum engine blocks have long been repaired using dry sleeves. Installing a repair sleeve can often save the block if a cylinder has excessive taper wear, or is cracked, scored or otherwise damaged, and boring out the damaged cylinder. Likewise, to restore the cylinders to like-new dimensions, all the cylinders in the block can be re-sleeved if all of the cylinders are heavily worn.

The main advantage of sleeving over boring out the cylinders and installing oversized pistons and rings is the cost savings of not having to replace the pistons and rings. Also, many blocks are too thin to reliably accommodate overboring without sleeves. And if we’re talking an aluminum block with integral iron sleeves, machining out the original sleeves and installing new ones may be the only way to save (or modify) the block.

For high performance applications, sleeves also offer a number of advantages. The displacement of an engine block is limited by the distance between the bore centers and the thickness of the casting. If the block is a heavy wall casting, you can increase the engine’s displacement by boring the cylinders to oversize and/or using a stroker crank. Stroker cranks are popular because they require fewer modifications. Long stroke cranks are good for low rpm torque, but a short stroke, large bore oversquare configuration is better for high revving power. Consequently, if you are building a high revving performance engine, you may want to increase the bore size rather than relying so much on increased stroke to create more power.

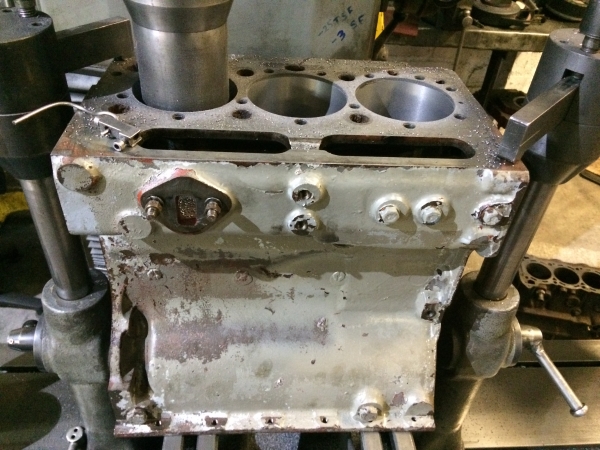

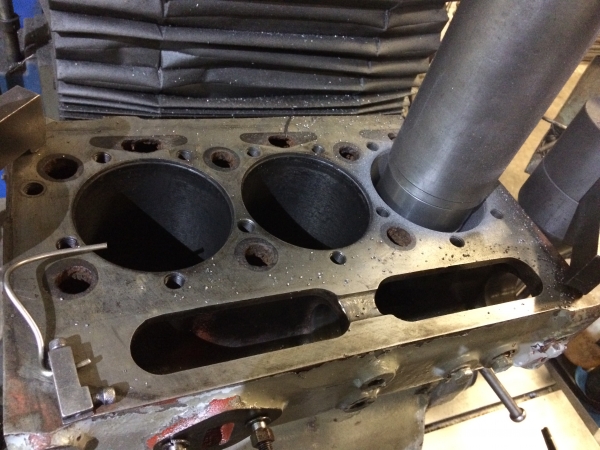

If you are installing dry sleeves in a block to increase displacement, you can remove only so much metal before you run out of block to support the larger cylinder sleeves. One way to overcome this limit is to do a wet sleeve conversion. The existing cylinders are machined away, and wet sleeves are installed in their place. Installation involves extensive modifications to the block so it can accept wet sleeves, but the results are worth it as the coolant is in direct contact with the outside of the sleeve, wet sleeves can typically handle much higher horsepower and heat loads. Consequently, you gain increased strength and reliability as well as more displacement. Wet sleeve conversion kits are available for certain late-model import engines as well as domestic V8s.

Audi RS4/6 v8 cylinder repairs

BMW M3 v8 cylinder repairs

Porsche 996 / 997 3.6 + 3.8

Porsche Cayman 3.4

Porsche 944

VW Transporter 2.5 AXD / BNZ